Technology

VERITASCAN time-temperature indicators are based on three principal innovations. First, a novel diffusion mechanism enables a gradual and programmable colour change to be produced within a label only 10 μm thick. Second, ink-processable molecular phase-change materials provide vivid colours, with a strong contrast between initial and final states of the indicator. Finally, adjusting the formulation of activator compounds fine-tunes the indicator performance to specific applications, including threshold temperatures as low as –80 °C for highly sensitive biopharmaceutical products such as mRNA vaccines and gene-based therapies.

Together, these innovations enable an exceptionally wide array of functionalities to be packed into an ultra-thin, flexible time-temperature indicator manufactured by common printing methods.

Polymeric phase-change materials feature vivid colours even in ultra-thin films. Above threshold temperature, irreversible colour change signifies a thermal excursion. Luminance contrast between the initial and final colours reaches 80%, enabling a rapid visual indicator reading even in low-light conditions.

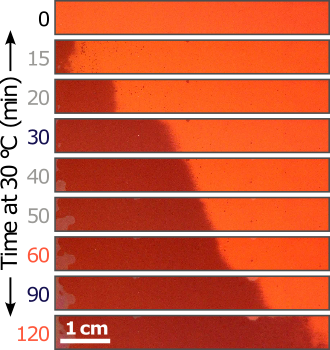

The example on the right shows a VERITASCAN indicator continuously registering a temperature excursion at 30 °C over a two-hour period. The progress of the dark bar is designed to progressively slow down over time, allowing both short- and long-term excursions to be accurately monitored.

The rate of spoilage processes becomes more rapid as the temperature is increased. Many cold-chain vaccines can remain relatively stable over several hours, or even days, at room temperature – but lose their potency within minutes upon reaching 40 °C when active cooling fails in hot climates.

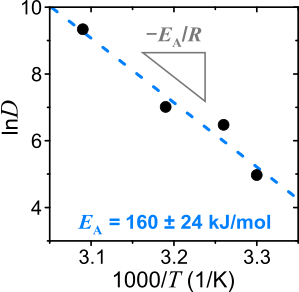

The Arrhenius activation energy quantifying such time-temperature response is a key parameter that needs to be matched between the product and the indicator for reliable monitoring. VERITASCAN indicators feature adjustable activation energies in the 94–160 kJ/mol range that are representative of common thermal degradation processes, providing an accurate measurement of residual shelf-life.

The combination of physical and digital indicator reading unlocks maximal flexibility for large-scale applications requiring traceability, inventory management or packing additional information into a small label format.

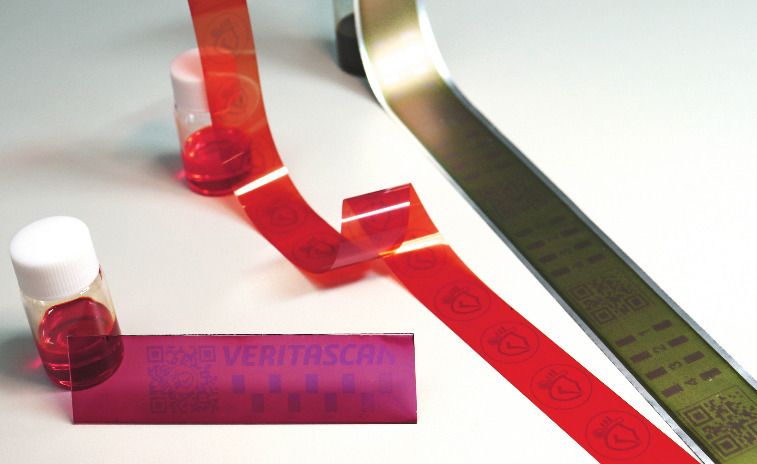

VERITASCAN indicators feature customisable pre-patterned markings such as QR codes that can be scanned by both professionals and general end-users. Digital printing allows each temperature-erasable code to be unique, enabling serialisation of indicators for optimised cold chain traceability and item-level applications.

VERITASCAN time-temperature indicators can be used as standalone devices or as adhesive labels applied to any product packaging. The example on the right shows an indicator attached to a vaccine vial cap, providing a temperature-erasable pictogram as a visual cue for temperature excursion

VERITASCAN indicators can be supplied as complete labels requiring chilled storage or as two-part labels that are conveniently ‘switched on’ at the point of entering the cold chain. Such on-demand activation facilitates storage at ambient conditions and ensures extended shelf life.

The example on the right shows the run-out of a two-part indicator brought above its threshold temperature.

VERITASCAN indicators are fabricated entirely by ink-based printing and coating methods that are fully scalable to high-throughput mass production. As shown below, the indicators can feature a variety of baseline colours to complement brand and product aesthetics, and are compatible with a wide selection of common substrates such as glass, plastic films and aluminium foils.